Elevator Smoke Protection

In the event of a fire, an unprotected elevator shaft acts like a chimney, spreading smoke through the subsequent floors. For that reason, per 2018 IBC §3006, elevator hoistways connecting more than three stories must comply with the smoke and draft control door assembly requirements and be tested in accordance with UL 1784.

The IBC requires buildings with elevator hoistways connecting three stories, to have a 1-hour fire-resistance barrier at the elevator shaft on each floor. When the elevator hoistway is connecting four or more stories, the barrier needs a 2-hour fire-resistance rating.

There are different solutions to meet IBC requirements, such as, smoke doors in front of the elevators, elevator shaft pressurization, enclosed lobbies with fire doors, and elevator smoke and fire curtains

1. Enclosed Lobby with Fire Doors

Per IBC, an enclosed elevator lobby shall be provided at each floor where an elevator shaft enclosure connects more than three stories. This alternative requires building an extra space at some distance from the elevator to create an elevator lobby. This elevator lobby will be closed by hold open smoke doors

Pros

- Low price

Cons

- Takes valuable space in commercial buildings

- They produce limitations for architects and designers

- Doesn’t allow for open-concept design

- Objects can stop the smoke doors from effectively closing when required

2. Elevator Shaft Pressurization

Elevator pressurization is a code-compliant option for elevator smoke protection and an alternative to enclosed elevator lobbies. This system is mostly used in tall buildings. Here, fans inject large quantities of air into the elevator shaft preventing smoke from entering the hoistway doors.

Pros

- Elevator shaft pressurization has been approved and adopted for a relatively long time.

Cons

- Design of pressurized elevators is complicated and expensive

- The system is costly to maintain

- Excessive pressures at some floors to achieve the minimum pressure differentials at all floors

3. Smoke doors in front of elevator

Hold open smoke doors can be installed directly in front of the elevator. The smoke protection doors are held open by a magnetic device and will close automatically in response to a fire alarm signal.

Pros

- The doors eliminate the elevator lobby requirement, providing more space for design freedom

- Low price

Cons

- Complicated installation (in combination with the wall)

- Bulky door visually unpleasing

4. Elevator Smoke Curtain

The Elevator Smoke Curtain can be installed almost invisibly in front of elevator openings.

During a fire event, the smoke containment curtain automatically deploys acting as a barrier to prevent smoke from spreading via the elevator shaft. Flexible magnetic strips are attached to the curtain’s edges to create a tight seal upon deployment. Elevator smoke curtains provide code-compliant smoke and draft opening protection.

Pros

- Visible transparent material

- Low price

- Smoke curtains eliminate the IBC Elevator lobby requirement, providing more space for design freedom

- Visually appealing

- The system can be hidden entirely in a suspended ceiling and will deploy only when needed

- Easy to install

- Low maintenance

- Allows for egress and access after the system is activated.

- The smoke curtain can be easily raised with the built-in emergency switch located in the center of the fabric

Cons

- Smoke curtains do not provide a fire rating

- Requires elevator frame without buttons or auxiliary rails

- One curtain for each elevator opening

5. Elevator Fire curtain

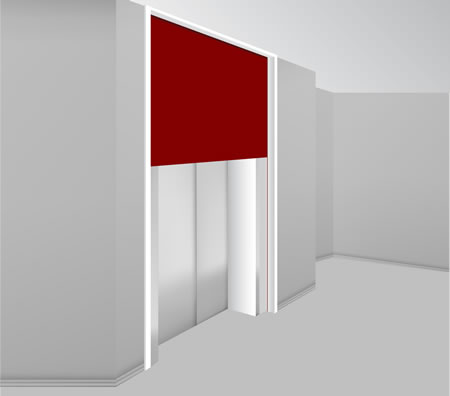

The Elevator Fire Curtain is installed in front of elevator openings and deploys automatically upon a fire alarm signal.

The Elevator fire curtain is a combined fire-rated door and a smoke containment curtain for elevators. This elevator curtain can be easily hidden with the correct framing. The side guides can be hidden by framing, and the headbox can be installed above the suspended ceiling.

Pros

- 1-hour or 2-hour fire rating

- Low price

- The fire curtain eliminates the IBC Elevator lobby requirement, providing more space for design freedom

- Visually appealing

- The system can be hidden entirely in a suspended ceiling and will deploy only when needed

- Easy to install

- Low maintenance

Cons

- The fabric is not transparent.

- Requires connecting to building emergency power

The Fire Curtain Technologies team of engineers is ready to help you find the right option for your next project. We provide design and code compliance support free of charge.